More Opportunities

More Opportunities

Get a head start on your flatbed training. Learn the language of open deck drivers!

Flatbed Truck Drivers Terminology

Learn the Lingo

Before you pull open deck, you need to understand the words and ways of flatbed truckers. You have a lot to learn, even if you’re an experienced dry van driver. With that in mind, we created a paid flatbed training program just for OTR drivers interested in high-paying flatbed trucking jobs.

The following guide will get you started.

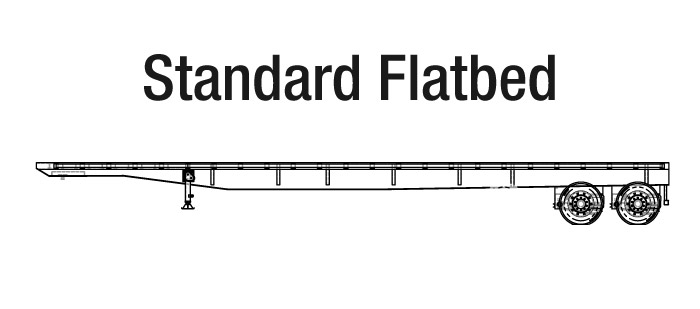

1. STANDARD FLATBED TRAILER

Flatbed training on standard trailers

Standard flatbeds share the following characteristics:

- Flat, level beds (with no sides or roofs, they’re often called “open decks”)

- Width less than or equal to 8’6″

- Height 60″ from the ground before loading

- Length 48′ to 53′

- Carry loads of up to 48,000 lbs.

Flatbed trucks haul cargo that won’t fit on standard pallets or in box vans. A flatbed trailer transports any bulky item its bed will hold. It’s especially suited to carry wrapped stacks of construction materials, oddly shaped parts or heavy equipment. Flatbeds are best for weather-resistant cargo that extreme conditions won’t damage.

The flatbed trailer’s chief advantage is quick and easy loading. Cargo comes on from the back at a dock, from the side by forklift or from overhead. For that reason, flatbed trailers are perfect for pickups and deliveries at off-road or unconventional locations.

2. LEGAL LOADS

No more than 13’6″ tall, 8’6″ wide and 53′ long

A “legal load” meets all federal size and weight rules and those of the states through which it passes. Regulations may vary in different jurisdictions but often require that loaded trailers fall within the above limits.

Specialty trailers often offer the flexibility to ship very tall or long items as legal loads. That’s important because loads that exceed legal dimensions are subject to many federal, state and local restrictions. (See “Over-Dimensional Loads” below.)

3. SECUREMENT

Flatbed training: securement first

A professional driver knows it’s critical to prevent loads from shifting. Obviously, freight must remain on the open bed and off the roadway. It also should stay put so the trailer always is balanced and stable.

The Federal Motor Carrier Safety Administration (FMCSA) issues detailed regulations on keeping cargo safely in place. Consequently, flatbed training focuses on securement. Drivers learn to prevent freight from tumbling off the deck or punching into the cab during a quick stop. Equally important, they practice fastening down cargo of all shapes and sizes.

New drivers also learn to avoid other hazards unique to flatbed driving. For instance, a driver often concentrates great weight or pressure in a small area during securement. Therefore, loosening winches or binders requires caution. Released too quickly or in the wrong order, straps and chains whip with dangerous force. Suddenly released, the load comes tumbling off the truck, endangering the driver and any bystanders.

Securement devices

To contain a load, some flatbeds have “drop sides,” hinged to fold down for loading. A “stake truck” uses steel uprights, often removable, for the same purpose. As an alternative, a carrier can install a “side kit.” (Scroll down for a detailed description.)

Most flatbed training concentrates on securing freight to open beds with nylon straps or steel chains.

- Flat webbing straps are more user-friendly and less likely to damage freight. They’re available in longer lengths for taller loads.

- Chains are stronger. While a 4″ nylon strap has a 4,000-lb. working load limit, a 3/8″ chain has a working load limit of 6,600 lbs. They’re more suitable than straps for heavy steel products. Chains also are less susceptible to abrasion on sharp corners. (Nylon straps need extra padding there.)

- A driver attaches straps to one side of the trailer with a metal hook. They connect the other side with a winch and tighten down the load.

- Chains loop through a stake pocket or “D” ring on either side of the trailer. A load binder takes up the slack in the middle of the chain to tighten the load.

Dunnage

“Dunnage” fills open spaces between cargo items and prevents shifting. It also creates space under or between cargo items, so a forklift blade slides in for easy lifting. Wood timbers commonly serve as dunnage.

4. TRAILERS THAT CONTAIN OR COVER THE LOAD

Side kit:

Equips a standard flatbed trailer with removable plywood or fiberglass side panels. These sidewalls provide a protective barrier when installed around heavy equipment or freight. They also offer structure and support for uncrated, unpackaged cargo. For instance, flatbeds equipped with side kits carry granular material like soybeans. They also haul small, loose objects like watermelons – or oddly shaped pieces like scrap metal.

Conestoga trailer:

A tarp and bow system that protects sensitive cargo from the elements. It works much like the enormous covered wagons that teams of oxen once hauled across the nation’s prairies.

A Conestoga trailer’s tarp system pushes back to leave the deck open for quick loading. Then, like the canvas on an old-time covered wagon, the tarp system slides back to surround the cargo. A Conestoga trailer offers the access and versatility of a flatbed with easy, secure protection that standard tarps can’t match.

5. TARPING

More flatbed training: tarping

Drivers cover some flatbed loads with tarps to protect against weather, wind, dirt or moisture. Thus, tarp securement is a critical part of flatbed training.

Usually made of heavy vinyl or PVC, tarps are water and tear-resistant. Rows of D-rings and grommets run their length in order to accommodate the ratchet straps, bungees or ropes that pull tarps tightly over cargo.

Tarps come in various shapes, weights and sizes to cover specific types of freight. The largest weighs 80 pounds when dry — far more when wet or icy.

Common tarps

-

Lumber tarps

Initially used for specialized lumber hauling. They’ve become all-purpose covers to protect pallets and other bulky cargo. Commonly 24’ wide and anywhere from 26’ to 30’ long, they cover large, high loads. The lumber tarp features a flap that folds down over one end of the load. The flap provides a tighter seal and prevents “parachuting” (when the wind fills and billows a tarp).

-

Steel tarps

Smaller than lumber tarps – typically either 12’ or 16’ wide and 24’ long. They are four-sided, without flaps. Steel tarps protect heavy loads with a low profile, such as steel rods, sheet steel and cables. They also provide “top only” protection for loads of crated material.

-

Smoke tarps

At 10’ or 12’ by 12’, among the smallest tarps. Also known as nose tarps, they cover the top front of a load, protecting against exhaust, bugs and road debris. They block wind from whistling through long pipes, too. Smoke tarps can also cover small portions of cargo on the open bed.

-

Coil tarps

Also called bag tarps because of their shape. They fit like snug caps over steel coils or cable spools, keeping them dry.

-

Machinery tarps

Protect valuable manufacturing or machine equipment from weather and road vibration. They cover the oversized, odd-shaped loads carried on specialty trailers. Many are custom sewn.

6. BULKHEAD OR HEADACHE RACKS

A safety barrier

These protect the driver from any cargo that breaks loose during a sudden stop.

- A headache rack is a reinforcing panel attached directly to the tractor’s frame, behind the cab or sleeper. If the cargo pushes forward, it knocks the cab off its frame rather than penetrating it.

- A bulkhead is attached to the trailer, on the end of the deck closest to the tractor. It blocks the cargo’s forward motion. Upon impact, the bulkhead bends, forcing freight up and over the cab as it moves forward.

Headache racks are standard equipment on many OTR cabs. On the other hand, flatbed trailers for local deliveries commonly use bulkheads.

7. OVER-DIMENSIONAL LOADS

Drivers begin flatbed training by learning to pull legal loads. They advance by hauling oversized freight. With experience, many OTR flatbed drivers also develop the skill and concentration necessary for super heavy hauling.

Permitted loads

While flatbed trailers are flexible, the nation’s road system is not. So, delivering oversized loads presents many technical, legal and logistical challenges. Lane width, bridge strength, signal height, ramp curvature and traffic patterns are just a few. It takes great care to drive safely in traffic with an oversized load.

That’s why it takes special permits, too.

To travel legally with an oversized load, a carrier must obtain a permit from every state through which it passes. Many cities and counties require permits, too. All permits are load-specific and valid for a limited number of days.

Over-dimensional truckers only move large or heavy units. In other words, if you can divide an oversized load into smaller legal loads, your shipment may not receive a permit.

Permitted loads are subject to federal, state and local safety restrictions. They might include any or all of the following:

- In most jurisdictions, permitted loads may move only during daylight hours, Monday through Friday, and not on holidays.

- Furthermore, the driver often follows pre-approved travel routes.

- The load may require paid police or civilian escorts along designated stretches.

- Additionally, the carrier may need to arrange the movement of overhanging signals or wires en route.

- The load may have to be marked by red safety flags, banners and amber lights.

- Loads wider than 11’6″ or taller than 13’6″ also may require pilot/pole/escort cars from origin to destination.

Super loads

Extremely wide, tall, long or heavy loads are known as “super loads.” The definition varies from state to state. A loaded truck over 16′ wide, 16′ tall, 160′ long or 200,000 lbs. qualifies in most. Super loads are subject to extensive permitting processes.

Specialized trucking companies like Lone Star often handle over-dimensional cargo. Our specialty trailers and expert drivers can handle the complex challenges of a permitted load.