More Opportunities

More Opportunities

Phenomenal equipment designed for oversized loads, all the way up to super heavy haul

Specialized Heavy Haul Jobs

A Truck Driver’s Guide

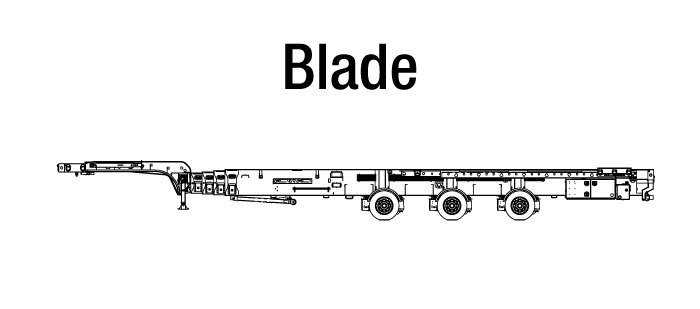

In specialized heavy haul trucking jobs, drivers pull oversized loads with special equipment. These trailers take on cargo that exceeds the dimensions of the legal load.

Below are descriptions of the best-known specialized trailers. All commonly carry permitted loads, and some also haul huge freight as legal loads. For example, step deck and drop deck trailers provide a few extra feet of clearance to keep some tall loads within overall height restrictions.

Keep reading for an introduction to the equipment used for heavy haul trucking jobs.

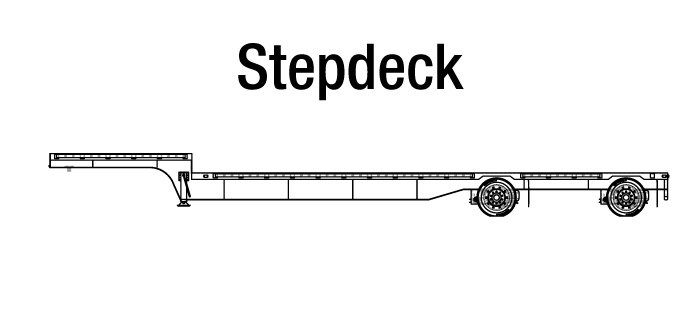

1. STEP DECKS - OR SINGLE DROP DECKS

Step Deck

Otherwise known as the single drop deck, this may be the best-known specialized flatbed trailer. Step decks are used both for legal loads and heavy haul trucking jobs.

The step deck trailer has two levels. Unlike a standard flatbed, the step deck’s bed drops down after clearing the tractor. The top deck is 60” off the ground, while the lower main deck is about 2’ lower.

Step deck trucking is used for tall loads. In fact, step deck trailers can carry cargo up to 10’ high as legal loads. For that reason, they commonly haul construction vehicles, machinery and heavy freight.

Because step deck trailers are so low to the ground, forklifts easily load them from ground level.

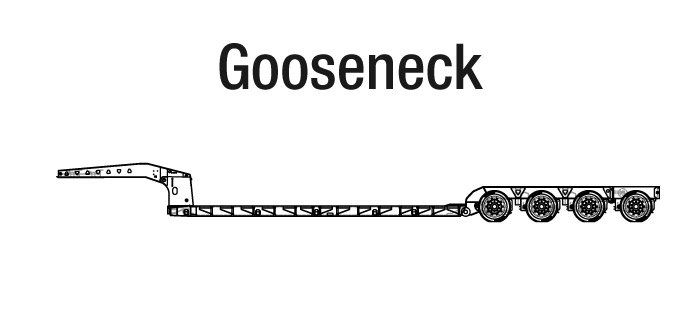

2. REMOVABLE GOOSENECKS (RGN) – OR DETACHABLES

Removable Necks

Some specialty flatbed trailers have removable necks. When detached and moved away from a trailer’s bed, an RGN’s front end lowers to the ground. This creates a ramp for self-powered cargo (e.g., heavy vehicles and equipment).

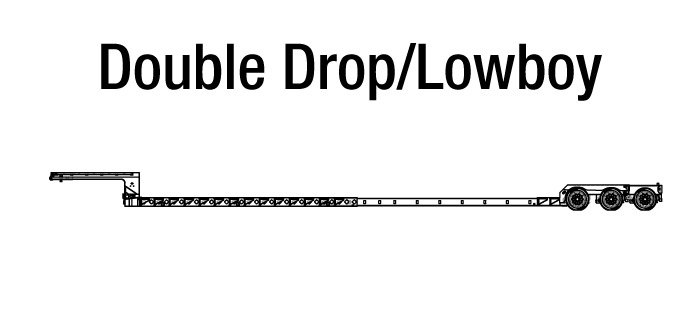

3. DOUBLE DROPS - OR LOWBOYS

Carrying Taller Loads

A double drop looks like a step deck or RGN in the front, but another short deck sits over its rear tires. Between the two short decks runs a low, extended main deck. Dropping below the trailer’s axles, this center deck is called the “well.”

The double drop trailer’s deep well and low-profile wheels allow it to carry legal loads with cargo up to 11’6” high. Heavy haul trucking jobs use double drops, too. Most have a “flip axle” to handle the weight of large loads. The flip axle attaches to a trailer’s rear frame with hinge plates and pins. Thus, the axle folds down for heavy loads and then backs onto the rear deck for storage.

RGN double drops carry vehicles that drive on for easy loading. That includes construction equipment, forklifts, trucks and tanks.

Conventional double drop trailers (those without RGNs) are often loaded by crane.

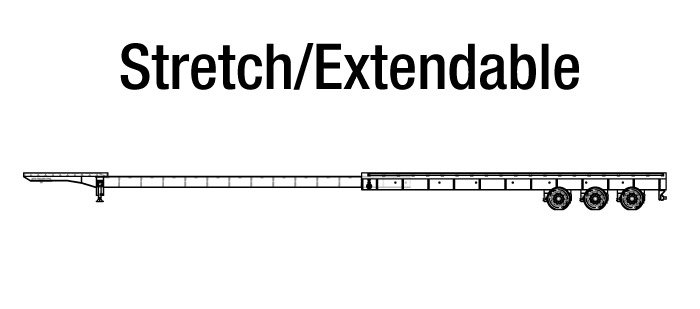

4. STRETCH & EXTENDABLE (TELESCOPIC) TRAILERS

Hauling Heavy Loads

Stretch trailers feature a sliding mechanism that grows or shrinks the size of the cargo bed, thereby adjusting to the ideal size for the load.

Stretch trailers come in flatbed, step deck, double drop and RGN configurations. You’ll find them in lengths over 80′ and widths of 96″ to 102″.

Generally of steel construction for maximum support, stretch trailers are heavy. So are their loads: lumber, rebar, trusses, steel beams, telephone poles. Total weight often limits the size of these loads.

5. OTHER SPECIALIZED TRAILERS

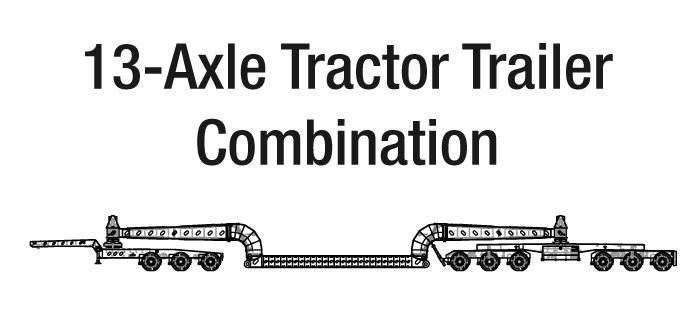

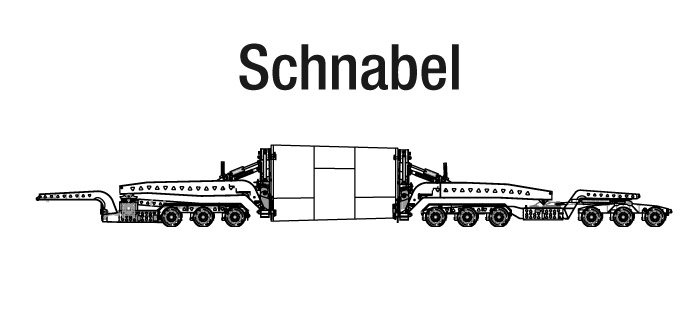

To carry an especially heavy load, a trailer needs more axles to distribute and support the weight.

Regulating Heavy Loads

States began regulating truck weights in the early 20th century. The first laws tried to prevent iron and solid rubber tires from damaging dirt or gravel roads. On the other hand, current law protects bridges and pavement from the weight of increasingly large loads.

Federal law limits gross truck weight to 80,000 lbs. Each state has its weight limits, typically 46,000 lbs. for legal loads and 80,000 lbs. with a routine permit.

Bridge Formulas & Heavy Haul Trucking Jobs

The Federal Bridge Formula sometimes further reduces the 80,000 lb. limit. (Many states have bridge formulas as well, most notably California). Bridge formulas calculate weight limits based on the number and spacing of truck axles in order to prevent the concentration of weight in short trucks or on small sections of long trailers.

Federal law also limits the total weight carried on any axle to the following:

Steer axle: 12,000 lbs. (or as rated by the manufacturer, not to exceed 20,000 lbs.)

Single axle: 20,000 lbs.

Tandem axles: 34,000 lbs.

Standard tandem axles are 5′ apart; they carry up to 34,000 lbs together.

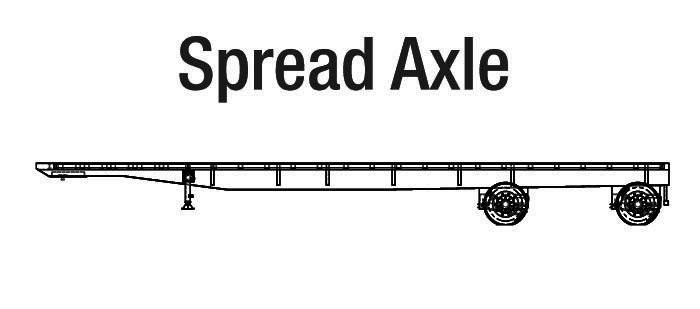

“Split” tandems, or “spread axles,” are at least 10′ feet apart. Under federal law, each axle counts separately when calculating per axle weight limits. Weight cannot exceed 20,000 lbs. per axle.

Spread axles provide flexibility when distributing weight between axles. Spread axle trailers also are more stable during loading and unloading.

While spread axles provide a smooth ride that is less damaging to road surfaces, their wider turning radius is challenging to maneuver. Tires, wheels, suspension parts and pavement all suffer when a driver turns too sharply.

The Ultimate Heavy Haul Trucking Jobs: Super Loads

Some shippers must move cargo far exceeding “routine permit limits.” The popular term for such freight also is its legal name: “super load.” Pulling a super load also is called “super heavy hauling” or “super heavy haul trucking.”

Without a doubt, transporting super loads is the most prestigious of heavy haul trucking jobs.

The definition of a super load varies from state to state. However, a loaded truck over 16′ wide, 16′ tall, 160′ long and/or 200,000 lbs. qualifies in most.

A Complex Permitting Process

Super loads require unique, often customized versions of flatbed and specialty trailers. They’re piloted only by the most skilled and experienced flatbed or heavy haul drivers. Even in expert hands, they present potential disruptions to traffic as well as risks to motorists and surroundings. That’s precisely why most states and cities tightly regulate them.

A state or city’s super load permitting process may require any or all of the following:

Listen to learn about the challenges Lone Star’s heavy haul drivers face

[viemo_video id=”742753904″]

- An engineering survey of the load and route

- Route survey to see that overhead signals, lines, railroad crossings and bridges don’t pose a hazard

- Bridge analysis determining the weight limit and axle configuration

- Analysis of traffic patterns and emergency vehicle routes

- Drawing of shipment

- Shipper’s letter

- Explanation of why other transportation isn’t available

- A practice run of the route

- Assignment of state-vetted escort support

- A schedule that accommodates day and time restrictions in different states. (In some states, super loads travel only during weekday daylight hours. In others, they move only at night or on a Sunday. Some jurisdictions prohibit travel during the spring thaw.)

- Surety bond

Lone Star is the recognized leader in planning, permitting and hauling super loads. Our drivers love the challenge of these heavy haul trucking jobs and get

paid more to take on ever-larger loads.

The Ultimate Heavy Haul Trucking Jobs: Super Loads

Some shippers must move cargo far exceeding “routine permit limits.” The popular term for such freight also is its legal name: “super load.” Pulling a super load also is called “super heavy hauling” or “super heavy haul trucking.”

Without a doubt, transporting super loads is the most prestigious of heavy haul trucking jobs.

The definition of a super load varies from state to state. However, a loaded truck over 16′ wide, 16′ tall, 160′ long and/or 200,000 lbs. qualifies in most.

A Complex Permitting Process

Super loads require unique, often customized versions of flatbed and specialty trailers. They’re piloted only by the most skilled and experienced flatbed or heavy haul drivers. Even in expert hands, they present potential disruptions to traffic as well as risks to motorists and surroundings. That’s precisely why most states and cities tightly regulate them.

Listen to learn about the challenges Lone Star’s heavy haul drivers face

[viemo_video id=”742753904″]

A state or city’s super load permitting process may require any or all of the following:

- An engineering survey of the load and route

- Route survey to see that overhead signals, lines, railroad crossings and bridges don’t pose a hazard

- Bridge analysis determining the weight limit and axle configuration

- Analysis of traffic patterns and emergency vehicle routes

- Drawing of shipment

- Shipper’s letter

- Explanation of why other transportation isn’t available

- A practice run of the route

- Assignment of state-vetted escort support

- A schedule that accommodates day and time restrictions in different states. (In some states, super loads travel only during weekday daylight hours. In others, they move only at night or on a Sunday. Some jurisdictions prohibit travel during the spring thaw.)

- Surety bond

Lone Star is the recognized leader in planning, permitting and hauling super loads. Our drivers love the challenge of these heavy haul trucking jobs and get

paid more to take on ever-larger loads.